What Makes a Manufacturer Your Trusted Choice for Demanding Applications?

Sourcing a critical component feels like a gamble. A cheap sight glass fails, causing catastrophic downtime and safety risks. You need a partner you can trust, not just a supplier.

A trusted sight glass manufacturer proves its worth through superior engineering, verified material quality, and deep application expertise. They provide certified components built to withstand your specific high-pressure, high-temperature, or corrosive environments without fail.

I've been in your shoes, Jacky. I remember sourcing a specific steel grade for a high-volume mold. The supplier cut corners, and the mold failed after just 10,000 cycles instead of the million we promised. That lesson cost me a lot of money and a client's trust. It taught me that the manufacturer behind the component is just as important as the component itself. It’s about partnership and proven reliability. This is why we focus on being a trusted manufacturer first and foremost.

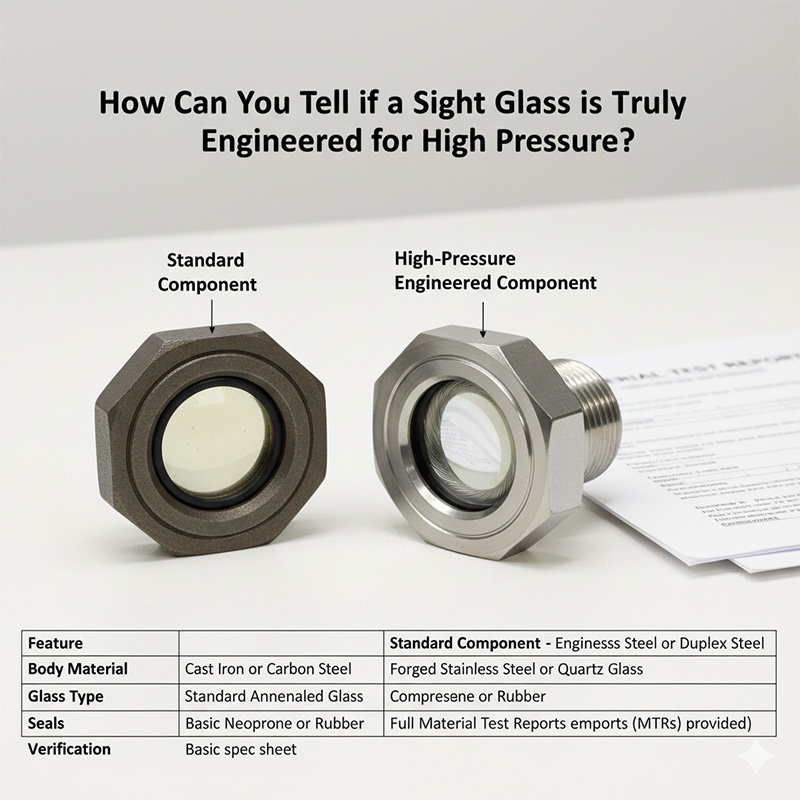

How Can You Tell if a Sight Glass is Truly Engineered for High Pressure?

You're looking at two sight glasses that seem identical. One is half the price. But how do you know if the cheaper one will hold up under 300 psi?

True high-pressure engineering is proven by material certifications and design specifications. Look for forged bodies over cast ones, tempered borosilicate glass instead of standard plate glass, and detailed pressure/temperature ratings supported by testing data.

The difference between a component that works and one that is truly safe is in the details you can't see. In manufacturing, these details are everything. A forged body, for example, has a much denser and more uniform grain structure than a cast one, making it far more resistant to cracks under pressure. It's the same reason critical engine parts are forged, not cast. The glass is another key area. Standard window glass would explode under thermal shock or pressure. We use tempered borosilicate glass, the same type used in laboratory equipment, because it's built to handle rapid temperature changes and high stress. It’s about choosing the right materials and processes for the job.

| Feature | Standard Component | High-Pressure Engineered Component |

|---|---|---|

| Body Material | Cast Iron or Carbon Steel | Forged Stainless Steel or Duplex Steel |

| Glass Type | Standard Annealed Glass | Tempered Borosilicate or Quartz Glass |

| Seals | Basic Neoprene or Rubber | Compressed Fiber or Spiral Wound Gaskets |

| Verification | Basic spec sheet | Full Material Test Reports (MTRs) provided |

Does Your Supplier Truly Understand Your Unique Application Needs?

You need a sight glass for a food-grade pipeline. A standard industrial model might fit, but will it fail a sanitary inspection and risk contaminating your product? That's a huge liability.

A true partner asks about your process first. They'll recommend specific materials like 316L stainless steel, appropriate seals like FDA-compliant Viton, and designs with minimal crevices to meet sanitary or chemical compatibility requirements.

This is where experience really matters. A simple parts seller has one solution for every problem. An engineering partner knows that the application dictates the design. It reminds me of designing injection molds. You can't use the same cooling channel layout for ABS plastic as you would for polycarbonate; the materials have different thermal properties. The same is true for sight glasses.

For Chemical Processing

In this environment, corrosion is the enemy. We would immediately move away from standard materials and look at corrosion-resistant alloys like Hastelloy or Duplex stainless steel. The sealing material is also critical; Teflon (PTFE) is often the only choice that can withstand highly aggressive chemicals.

For Sanitary Applications

Here, it's all about preventing bacterial growth. The sight glass body must be made from 316L stainless steel with a highly polished, crevice-free surface. Connections would likely be tri-clamp fittings, which are easy to disassemble and clean thoroughly, and all sealing materials must be FDA-approved.

For High-Temperature Systems

For steam lines or hot oil systems, thermal shock is the biggest danger. We use borosilicate or even quartz glass, which can handle extreme temperature swings, paired with graphite-based gaskets that won't degrade or become brittle under intense heat.

Is Your Manufacturer a Partner or Just a Parts Seller?

The part has arrived, but you have questions about installation torque or need a material certification for a safety audit. Your supplier is now silent, leaving you completely on your own.

A partner provides comprehensive support. This includes clear installation guides, accessible technical experts, and readily available documentation like material test reports and pressure test certifications. Their job isn't done until your system is running safely.

When I was running my CNC trading company, the sale was just the start of the relationship. The real value my clients saw was in the support we offered after the machine was delivered—training, troubleshooting, and maintenance advice. That’s what built the trust that led to repeat business. A component manufacturer should be no different. You're not just buying a piece of metal and glass; you are buying the assurance that it will perform as promised. That assurance comes from the support structure behind the product. A good partner should be able to provide all necessary documentation without hesitation and have an engineer available to answer your technical questions. This support is your insurance policy against failure.

Conclusion

Choosing a manufacturer is about ensuring reliability and safety. A trusted partner delivers engineered quality, application expertise, and unwavering support, protecting your operations from risk and potential downtime.