Threaded-connection Bulls Eye sight glass units offer the highest pressure and temperature service of any sight glasses.

Bulls Eye units are available for 1/8″ to 2″ MNPT pipe thread connections, and can be manufactured to meet your pressure and temperature requirements. Different materials of construction are available to meet your process needs. This unit can be utilized with other types of connections including NPT plug, weld, socket-weld, flange, sanitary, or as specified.

In addition to their high pressure and temperature capabilities, threaded-connection Bulls Eye sight glass units are also highly versatile. They can be used in a variety of applications thanks to their compatibility with different types of connections, including NPT plug, weld, socket-weld, flange, and sanitary connections. This makes them ideal for use in industries such as food and beverage, pharmaceuticals, and chemicals.

Moreover, the availability of different materials of construction ensures that the Bulls Eye sight glass units can be designed to meet the specific process needs of different industries and applications. For example, units made from certain materials may be more suitable for use in highly corrosive environments, while others may be better suited for use in higher temperature applications.

Overall, if you are looking for a sight glass unit that offers both high performance and versatility, a threaded-connection Bulls Eye sight glass unit could be an excellent choice for your application.

Expert Tips for Selecting a Bullseye Sight Glass

When it comes to industrial applications involving fluid monitoring, selecting the right sight glass is crucial. A bullseye sight glass, with its unique design allowing for easy visibility of liquid levels, is a popular choice. However, choosing the perfect one for your specific needs requires careful consideration. In this article, we will provide you with expert tips to help you select a bullseye sight glass that meets your requirements and ensures optimal performance.

1. Understand the Purpose:

To begin the selection process, it is essential to understand the purpose of the bullseye sight glass in your application. Determine the fluid type, operating conditions (such as temperature and pressure), and any specific requirements for monitoring or maintenance. This initial assessment will help you identify the necessary properties of the sight glass.

2. Material Selection:

Consider the materials used to manufacture the bullseye sight glass. Common options include borosilicate glass, acrylic, and polycarbonate. Borosilicate glass offers excellent chemical resistance, clarity, and durability. Acrylic is lightweight, UV-resistant, and cost-effective for applications with lower pressure and temperature requirements. Polycarbonate combines the durability of glass with the impact resistance of acrylic, making it suitable for applications with high levels of physical stress.

3. Pressure and Temperature Ratings:

Evaluate the pressure and temperature ratings of the sight glass to ensure it can handle the operating conditions of your application. Bullseye sight glasses typically have pressure ratings ranging from a few psi to higher values, depending on the materials used and design. Temperature ratings also vary, and it is crucial to choose a sight glass that can withstand the temperature extremes within your application.

4. Size and Visibility:

Consider the size of the bullseye sight glass that would best suit your needs. The diameter of the glass and the thickness of the housing should be appropriate for your application. Additionally, evaluate the visibility of the liquid level through the sight glass. It is crucial to ensure clear visibility in various lighting conditions for accurate monitoring.

5. Sealing and Gasket Material:

Pay attention to the sealability of the bullseye sight glass. Look for designs that provide a reliable and leak-free seal, guaranteeing a secure installation. Additionally, the gasket material used should be compatible with the fluid being monitored to avoid any degradation or chemical reaction that could compromise visibility or safety.

6. Accessories and Additional Features:

Consider any additional features or accessories that might enhance the functionality of the sight glass. Some bullseye sight glasses may come with built-in valves, drain plugs, or indicators for quick and easy maintenance or monitoring. These extra features can simplify operations and offer added convenience.

Conclusion:

Selecting the correct bullseye sight glass is crucial for efficient fluid monitoring in industrial applications. By understanding the purpose, considering materials, evaluating pressure and temperature ratings, ensuring clear visibility, and paying attention to sealing and gasket materials, you can make an informed decision. Remember to assess any additional features or accessories that align with your specific requirements. With the right bullseye sight glass, you can achieve accurate fluid level monitoring and ensure smooth operations in your industrial setup.

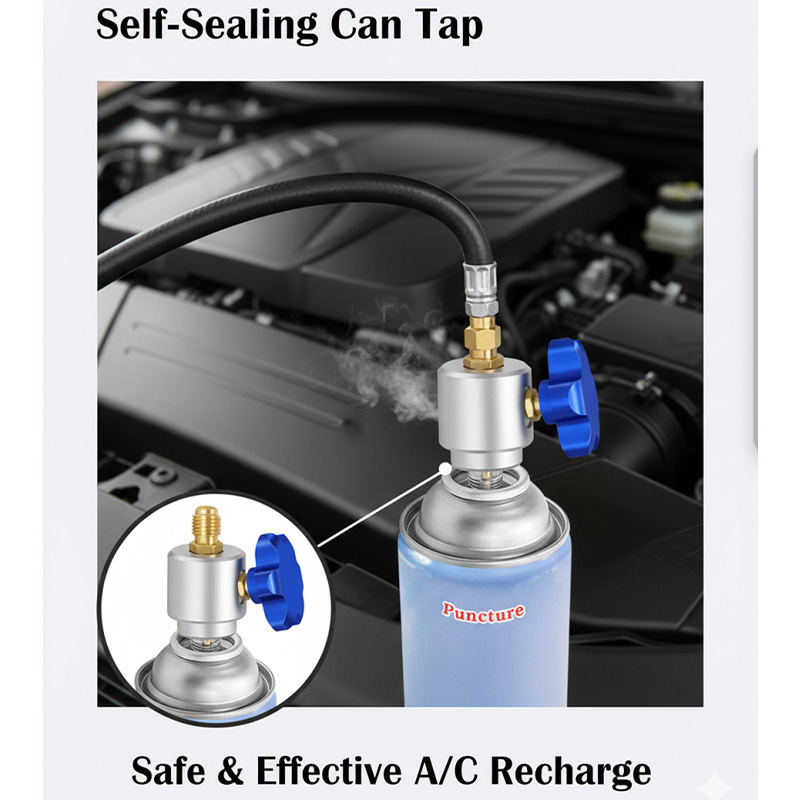

HOT SELLING RECOMMENDATIONS

FSG037-2 3/4” NPT Stainless Steel Oil Sight Glass with Ball Indicator for Water and Oil Hydraulic Tank Sight Glass