Is It Time to Design Your Own Custom Flow Control Parts?

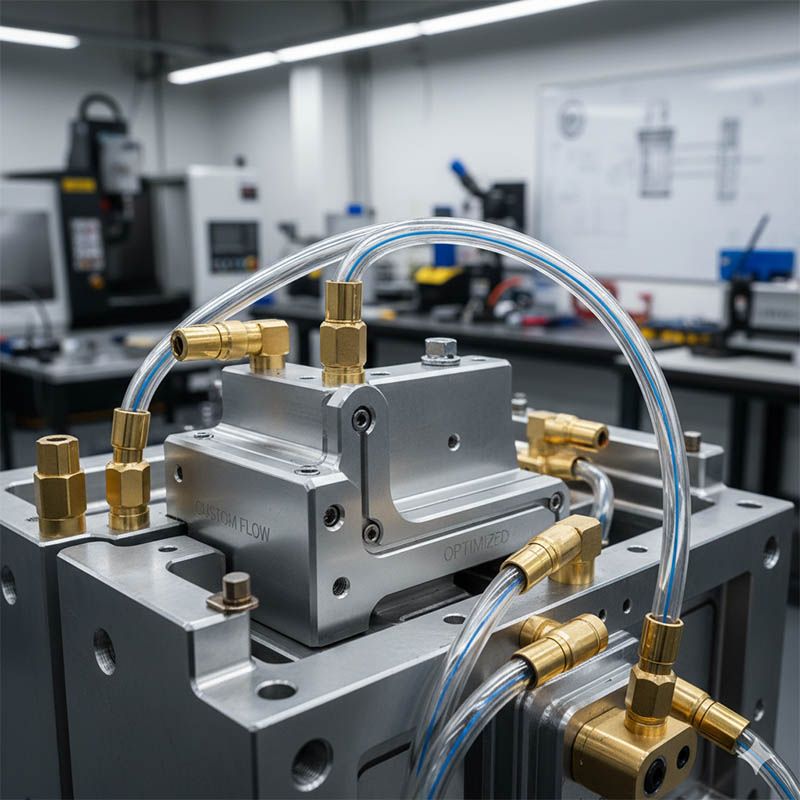

You're stuck trying to plumb a complex mold. Standard fittings create clumsy hose routes, restrict flow, and introduce multiple potential leak points. The perfect solution simply doesn't exist off-the-shelf.

Yes, it is time to go custom when standard parts compromise your design's performance, reliability, or serviceability. Designing a custom manifold, adapter, or fitting is the professional solution for optimizing flow paths, integrating features, and solving unique challenges in high-performance molds.

I once worked on a project for a medical device that had an incredibly complex core with very specific cooling requirements. We spent days trying to connect a web of standard brass fittings and hoses to get water to all the right spots. It was a nightmare. The assembly was fragile, it leaked from three different places, and we knew it would be impossible to service. Frustrated, my lead engineer and I stayed late one night. We took a block of scrap aluminum and sketched out a simple manifold that did the job of a dozen different fittings. We sent the sketch to our internal machine shop, and two days later, we had this beautiful, simple part that solved everything. It cost a bit more upfront, but it saved us weeks of headaches and made the final mold immeasurably better. That taught me that sometimes, the "easy" way is actually the hardest way.

How Do You Justify the Cost and Lead Time of a Custom Part?

You see the perfect custom solution in your head. But your project manager sees a high price tag and a three-week lead time. How do you prove this isn't just an expensive engineering whim?

You justify it with a business case, not a technical one. Focus on the Total Cost of Ownership (TCO). A custom part that eliminates downtime, simplifies assembly, or shaves a fraction of a second off the cycle time will pay for itself many times over.

For a designer like Jacky, getting buy-in from management is half the battle. They speak the language of money and time. You have to translate the technical benefits of your custom part into their language. Don't just say "it's more efficient." Say "it reduces cycle time by 0.3 seconds, which translates to an extra 5,000 units per month and a revenue increase of $15,000." You need to move the conversation from upfront cost to long-term value. This requires doing a little homework, but it’s the key to getting your best ideas approved.

Calculating the Total Cost of Ownership

The initial price of a custom part is only one piece of the puzzle. You need to compare that to the hidden costs of a "cheaper" off-the-shelf solution. This includes the cost of multiple fittings, the extra labor time for a complex assembly, and, most importantly, the massive cost of potential production downtime caused by having more leak points. A single hour of a molding machine being idle can cost hundreds or even thousands of dollars.

Presenting Your Case to Management

Create a simple comparison table. On one side, list the off-the-shelf solution. On the other, list your custom solution. Show the numbers clearly. The goal is to make it obvious that while the initial part cost is higher for the custom option, the overall value and risk reduction make it the smarter financial decision.

| Cost Factor | Off-the-Shelf Assembly | Custom Manifold |

|---|---|---|

| Initial Part Cost | $75 (10 fittings + hose) | $250 (1 manifold) |

| Assembly Time | 45 minutes | 10 minutes |

| Potential Leak Points | 12 | 3 |

| Est. Downtime Risk | High | Low |

| Performance | Adequate Flow | Optimized Flow (-0.2s cycle time) |

| Long-Term Value | Low | High |

What's the Best Way to Design and Source Custom Metal Parts?

You've got the green light to design a custom part. Now the pressure is on. How do you make sure the part you design is manufacturable, high-quality, and delivered on time?

The key is early collaboration and clear communication. Engage with your machine shop or supplier during the design process. Use Design for Manufacturability (DFM) principles and create a crystal-clear technical drawing that leaves no room for interpretation.

Nothing is more frustrating than spending days on a design only to have a machinist tell you it's impossible or extremely expensive to make. I learned early on to treat my machinists as partners, not just suppliers. Before I finalize a design for a custom part, I send them a preliminary model. I ask simple questions: "Is there an easier way to make this? Can we use a standard tool size here? Is this tolerance too tight?" This five-minute conversation can save thousands of dollars and weeks of delays. It's about respecting their craft and leveraging their expertise to make your design better and more practical.

Design for Manufacturability (DFM) First

DFM means designing your part in a way that makes it easy and cost-effective to produce. For machined parts, this means avoiding overly complex surfaces, using standard hole sizes and thread taps, designing generous corner radii to allow for larger tools, and keeping tolerances as loose as possible while still meeting your functional requirements. Every tight tolerance adds cost.

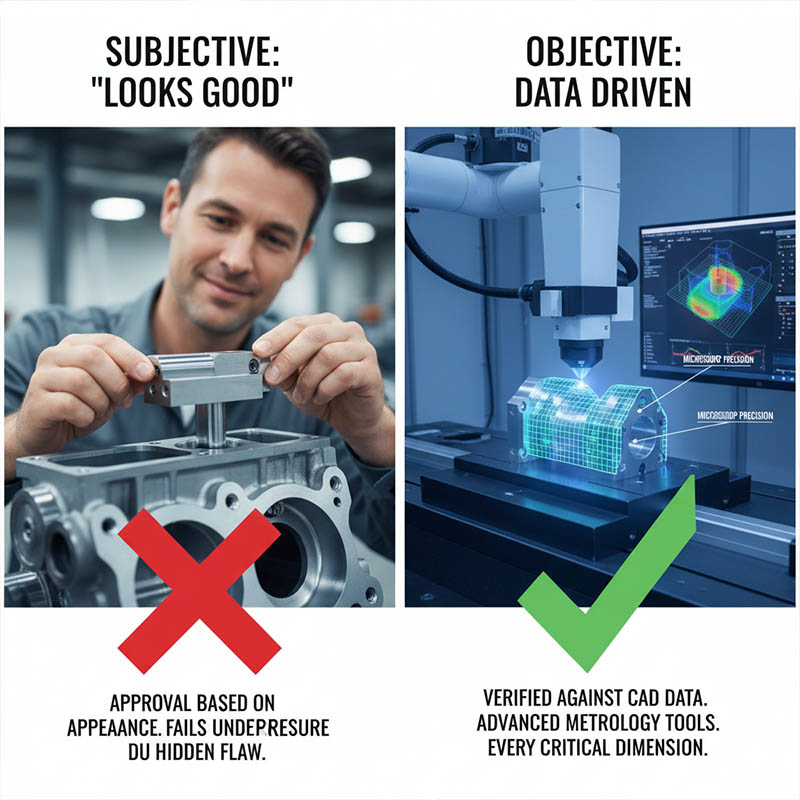

Create a Bulletproof Technical Drawing

Your drawing is your contract with the machine shop. It must be perfect. It is the single source of truth for your part. Be sure to include all critical information clearly.

| Drawing Element | What to Include | Why It's Critical |

|---|---|---|

| Material Specification | Exact alloy and temper (e.g., Aluminum 6061-T6) | Ensures the part has the right strength and corrosion resistance. |

| Critical Dimensions | Use clear datums and specify only necessary tolerances. | Over-tolerancing is expensive; under-tolerancing causes failures. |

| Surface Finish | Call out Ra values for sealing faces or critical bores. | Guarantees a leak-proof seal for O-rings or gaskets. |

| Threads & Ports | Specify type and class (e.g., 1/4" NPT, M5x0.8 - 6H). | Ensures standard fittings will connect perfectly. |

| Final Inspection | Note any special requirements like pressure testing. | Provides final validation that the part meets your requirements. |

Conclusion

Custom metal parts are a powerful tool in your design arsenal. By justifying them with TCO and designing them for manufacturability, you can create superior, reliable, and highly-optimized flow control systems.