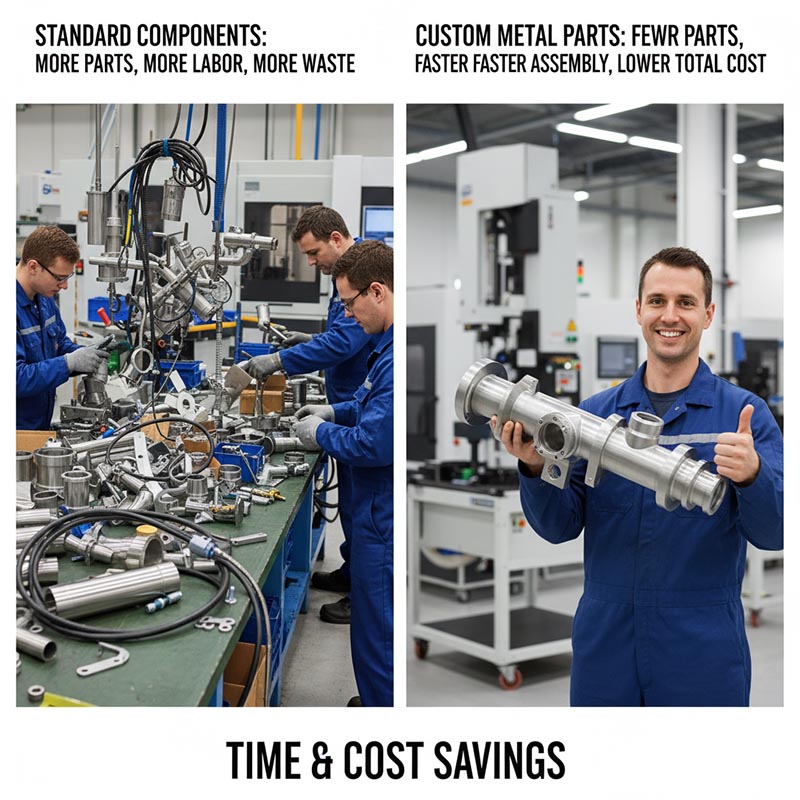

How Can Custom Metal Parts Actually Save You Time and Cost?

You need a specific part, but a custom solution feels too expensive. So you design around standard components, adding complexity, extra fittings, and unexpected labor costs down the line.

Custom parts save money by reducing component counts, eliminating assembly labor, optimizing material usage, and integrating features that would otherwise require costly secondary operations, leading to a lower total cost.

I remember working with a client who designed industrial automation equipment. They were building a safety guard assembly using off-the-shelf slotted angle iron, a dozen L-brackets, and a bag full of nuts and bolts for each unit. Their assembly team was spending hours on each one, fighting with alignment issues. The final product looked clumsy and was a nightmare to put together. I sat down with their designer—a smart guy like you, Jacky—and we drew up a single part. It was a laser-cut and bent sheet of steel with all the mounting holes and access windows built right in. The per-piece cost was higher than one L-bracket, of course. But it replaced 17 individual parts, cut assembly time from two hours to ten minutes, and was stronger and looked far more professional. They saved a fortune on labor and improved their product in the process.

Can a Single Custom Part Really Replace a Multi-Part Assembly?

Your design has too many screws, brackets, and shims. It's becoming a nightmare to assemble, and the tolerance stack-up from all the pieces is causing fitment issues.

Yes. By combining multiple functions into a single, intelligently designed custom component. This dramatically reduces manual assembly time, eliminates fasteners, and improves the overall strength and accuracy of the final product.

Think about the compounding costs of a complex assembly. You have the cost of each individual part, the cost of all the screws and washers, and most importantly, the labor cost for a person to pick up each piece and fasten it together. Every additional part introduces another potential point of failure and another tolerance that can stack up and cause problems. A single custom part, designed for the exact task, eliminates all of that. It's an approach called Design for Assembly (DFA). Instead of forcing a design to work with standard parts, you design the part to perfect your assembly process. The result is fewer items to order, stock, and manage; a faster and more foolproof assembly process; and a stronger, more rigid final product because it’s made from one solid piece.

Standard vs. Custom: A True Cost Comparison

| Factor | Standard Parts Assembly | Single Custom Part |

|---|---|---|

| Part Count | 5-10+ unique components | 1 component |

| Fastener Count | 10-20+ nuts and bolts | 0 (integrates into frame) |

| Assembly Time | 30 minutes | 2 minutes |

| Tolerance Stack-up | High risk of misalignment | Minimal to none |

Is Buying 'Off-the-Shelf' Forcing You to Over-Engineer Your Designs?

You choose a standard I-beam because it's available. But you know it's much heavier and more expensive than you really need, adding unnecessary weight and cost to your project.

Often, yes. A custom part lets you use the exact material and geometry needed for your specific load, verified by analysis. This avoids paying for excess material and weight inherent in generic, one-size-fits-all components.

Standard structural shapes and plates are made for general-purpose use. They are designed to be "good enough" for thousands of different applications, which means they are rarely "perfect" for yours. A standard steel bracket might be 5mm thick because it needs to handle a huge load in some applications, but your specific use might only require 3mm of thickness. That extra 2mm is material you paid for but don't need. When we create a custom solution, we start with your exact requirements. We can use tools like Finite Element Analysis (FEA) to simulate the stresses on the part and strategically remove material from low-stress areas. As a designer, Jacky, this gives you immense freedom. You can optimize for strength while minimizing weight, which is critical in everything from robotics to aerospace, and it directly reduces the cost of raw materials.

The Optimization Advantage

-

### Material Selection You aren't stuck with standard A36 steel. If your part needs to be lightweight, we can design it in aluminum. If it needs corrosion resistance, we can make it from the appropriate grade of stainless steel right from the start.

-

### Geometry Optimization We can design a part that is thicker and stronger only where the stress is high, and thinner and lighter everywhere else. This a level of efficiency that is impossible to achieve with off-the-shelf parts.

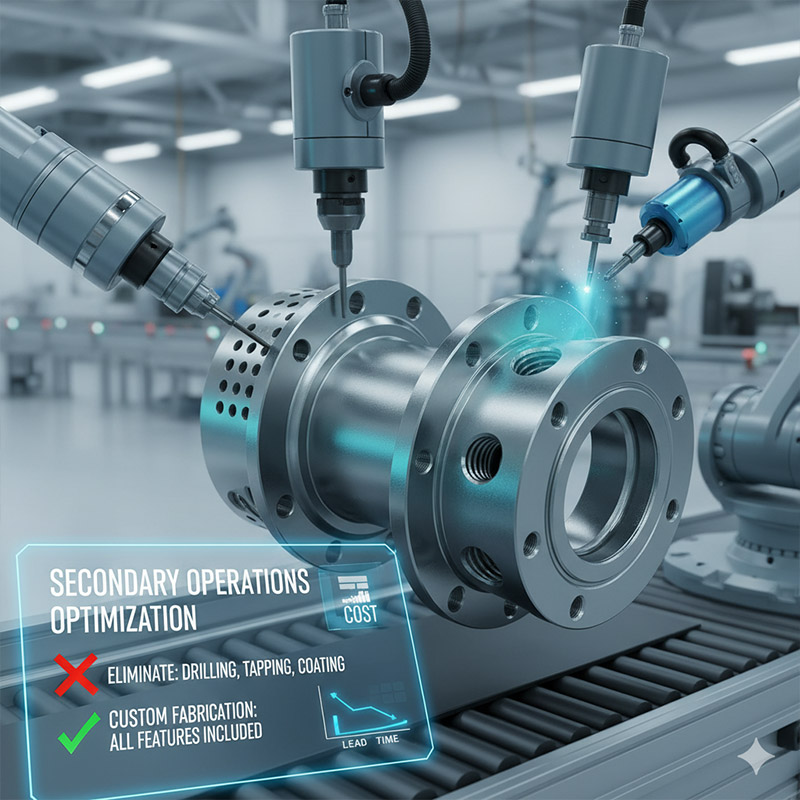

Are Secondary Operations on Standard Parts Killing Your Budget and Schedule?

You buy a standard part, but then you have to drill holes, tap threads, and send it out for coating. Each step adds cost, lead time, and management overhead.

Absolutely. A custom part can be fabricated with all features—like threaded holes, countersinks, locating pins, or specific coatings—included in the initial manufacturing process, saving significant time and logistical headaches.

This is a huge hidden cost that many people forget to calculate. The price of that "standard" angle iron looks great. But then you have to pay a fabricator to cut it to length. Then they have to put it on a drill press to make holes. Then someone has to tap threads into those holes. Each of these steps costs labor time and adds days or weeks to your lead time. With a modern custom fabrication process like laser cutting or CNC machining, all of these features can be created in a single operation. The machine can cut the outline, create the holes, and even etch part numbers all at once. This collapses your supply chain, reduces your lead time, and gives you a far more precise and repeatable final product without the extra steps.

The "Hidden Factory" of Secondary Operations

| Operation | Associated Cost | Added Lead Time |

|---|---|---|

| Cutting to Length | Labor, machine time, scrap | 1-2 days |

| Drilling / Tapping | Labor, risk of error/tool breakage | 1-3 days |

| Sending to Plater | Vendor management, shipping, invoicing | 1-2 weeks |

Conclusion

Embracing custom parts is about designing smarter. They reduce complexity, optimize material, and eliminate extra steps, leading to a leaner process and a lower total project cost.